Laminated tubes are known to provide a unique presence to the products in the market and they are used widely for packaging in Pharmaceutical, Oral Care, FMCG, Cosmetics, Healthcare industries and other applications all over the world.

Over 70% of Lami Tubes produced are used in oral care industry. In addition, laminated tubes manufacturers and suppliers are also supplying these products to the cosmetics sector.

Laminated Tubes are known for great barrier properties and they are cost-effective way to help improve the shelf life of a product. They are known for soft, smooth, and flexible exteriors to deliver great salability and high filling speed in the process of packaging.

Benefits of Laminated Tubes

Multilayer tubes with Aluminum foil / EVOH / nylon / polyester act as barrier against oxygen, moisture, Aroma loss and provide a glossy surface enhancing printing quality.

Optional barriers can be applied to the shoulder for the same purpose.

Multi layer five to eleven layers or plastic with EVOH/Nylon as barrier material is useful for the cosmetic and Pharmaceutical industry.

Length of the tube can vary from 70 to 200 mm.

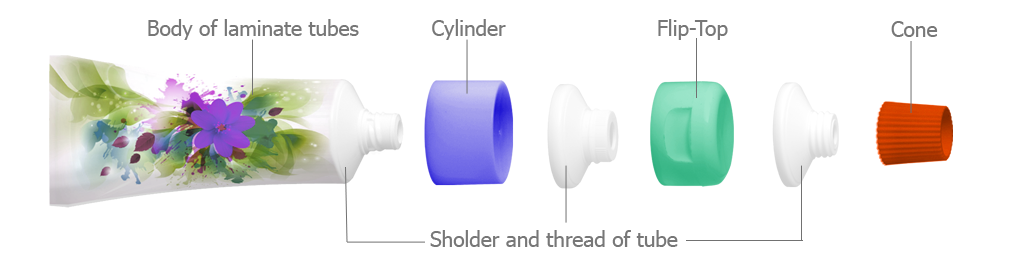

Different caps such as conical, flip-top, standy and the like can be custom designed for an aesthetic look.

Laminate has both the look and feel of a plastic and properties of aluminum tube. Hence, companies can get the best of both worlds. The latest laminate tubes come with the benefits of cutting-edge technology.

Laminated Tubes Manufacturers & Exporters

Today, laminated tubes suppliers and exporters in the USA, UK and UAE also offer a tube made with most appealing minimal seam in the industry to ensure proper space for brand decoration and graphics.

The laminate material also avoids the transfer of air, light, and moisture. Lami tubes suppliers and exporters also provide the widest array of graphics on tube with different styles and sizes. They can also make tube as small as 12.7mm (0.5 inch) in diameter.

Laminated Tubes – The Process

Manufactured by the top Lami Tubes Suppliers and exporters in the world, laminated tubes are made with a flat web stock. Then, it is printed as per your specifications on the rotogravure equipment or top quality letterpress.

Then, the printed output takes a tubular shape, cut as per the desired length to turn a sleeve. Then, it is attached to the molded shoulder. Lami Tubes manufacturers and suppliers can add tamper-proof sealed membrane to protect the product.

Finally, the tube is checked, capped, and packed. It is a complete integrated system and the whole package is assembled well in line.

Laminated Tubes Products