Choose EvoPacks

The Reasons You Should Use Laminated Tube

Barrier Protection: Laminated tubes provide exceptional barrier protection for the contents they hold. The combination of aluminum foil and plastic layers creates a robust and impermeable barrier that shields products from external factors such as moisture, light, and air. This is particularly valuable for sensitive products like pharmaceuticals, cosmetics, and food items, as it helps maintain product integrity, freshness, and shelf life.

Versatility and Customization: Laminated tubes are highly versatile and customizable. Manufacturers can choose from a wide range of sizes, shapes, and printing options to create packaging that perfectly suits their brand and product requirements. The ability to print intricate designs, logos, and product information directly on the tube enhances branding and product visibility, making them a valuable marketing tool.

Eco-Friendly Solutions: Many laminated tube manufacturers are increasingly adopting eco-friendly practices by using recyclable materials and reducing environmental impact during production. This aligns with the growing consumer demand for sustainable packaging options. Laminated tubes can be recycled, further contributing to environmental sustainability and reducing the overall carbon footprint of the packaging industry.

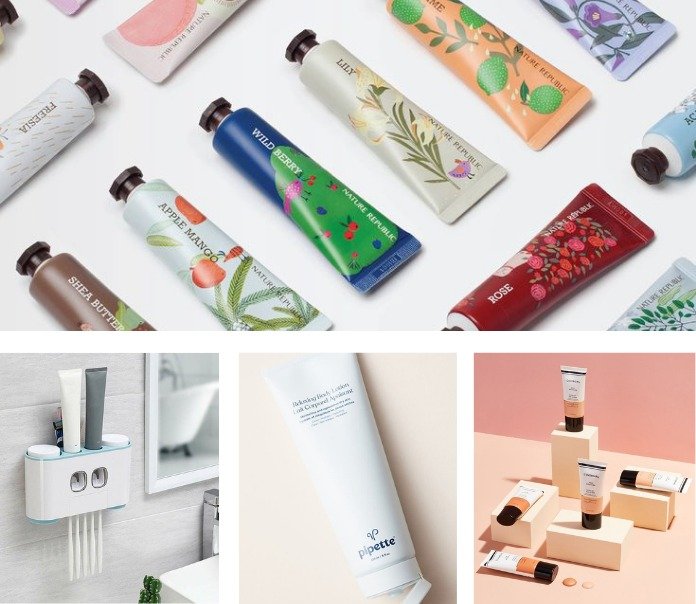

Laminated Tubes Products

CUSTOM MOULDING

DECORATION & PRINTING

THE MARKET SECTORS WE CATER TO WITH ALL OUR HEART

PERSONAL CARE

HEALTH CARE

AGRICULTURE

AYURVEDIC & VETERINARY

ABOUT US

OUR CONTACTS

- +91-9538765555

- info@evopacks.com

REGISTERED ADDRESS

3rd , Sai Nilayam Manikya Nagar 5th Line , Opposite Invicon Navah, Kanuru, Vijaywada,Andhra Pradesh - 520007